YOUR NO 1 WOODWORKING POWER TOOLS RESOURCE WEBSITE

Do You Need a Laser Engraver For Woodworking? (A Beginners Guide)

Disclosure: If you click on some of the links, we may earn a small referral fee. Please know that we only recommend products that we use and believe will add value to our readers.

Laser engravers are becoming increasingly popular in the woodworking community. They offer a high level of precision and detail that is not possible with traditional methods.

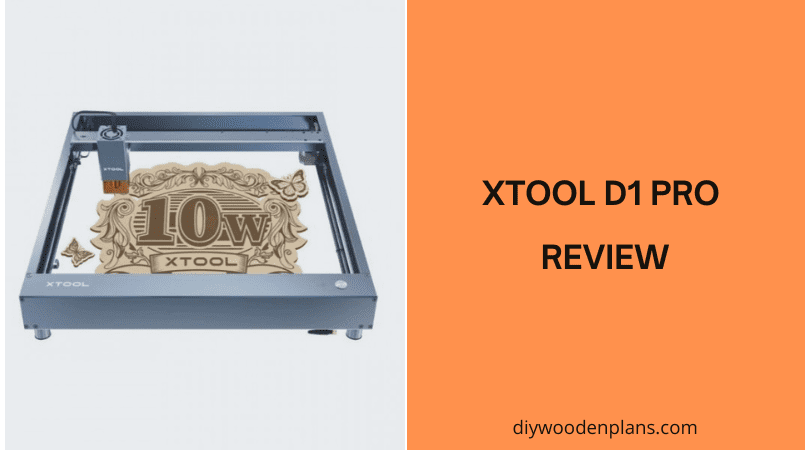

In this article, We will discuss the benefits of having a laser engraving machine and how it can help make your projects more precise and beautiful. We will also review two of the best laser engravers in the market to help you make an informed choice.

So, read on to find out why you need a laser engraver for woodworking!

What are Laser Engravers & How Do They Work?

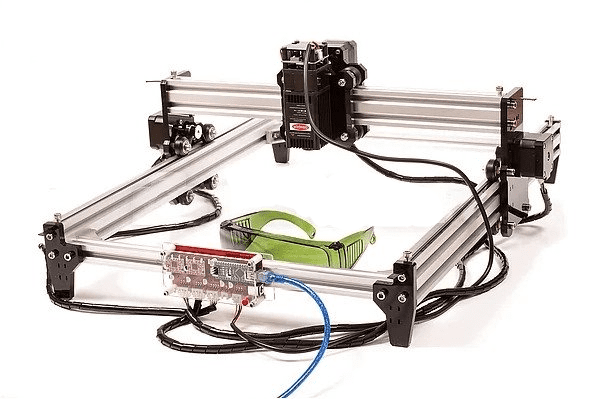

Laser engravers are machines that use a laser beam to engrave or mark a material by removing material from its surface.

They work by directing a high-power laser beam onto a material, such as wood, metal, plastic, or glass. The laser’s energy is then used to vaporize or remove material from the surface.

The laser beam is focused and controlled by a set of mirrors and lenses, allowing it to be directed precisely onto the material.

The laser engraver typically includes a computer control system that manages the laser beam and guides its movement across the material being engraved.

The computer control system also inputs the design that is to be engraved and controls the laser beam’s movement and power level. This ensures that the desired pattern or design is accurately produced.

What Materials Can a Laser Engraver Engrave?

A laser engraver can engrave a wide range of materials, including:

Wood: Engraving machines are commonly used on wooden materials such as plywood, hardwood, MDF, balsa wood, and more. See our guide to selecting the best wood for laser engraving and cutting

Acrylic: Acrylic is a popular material for laser engraving due to its transparency and durability.

Glass: Laser engraving on glass can produce stunning results, making it ideal for creating personalized gifts, awards, and trophies.

Metal: Laser engravers can be used on certain types of metal, including stainless steel, titanium, and aluminum.

Leather: Leather is a versatile material that can be engraved to create custom designs on bags, wallets, and other leather items.

Paper and cardboard: Engraving machines can be used on paper and cardboard to create intricate designs on invitations, business cards, and packaging.

Stone: Laser engraving on stone materials such as marble, granite, and slate can produce highly detailed and intricate designs.

It’s important to note that some materials, such as PVC and vinyl, release toxic fumes when engraved, hence they should be avoided.

Always check the manufacturer’s instructions for any material before attempting to engrave it with a laser.

What are The Different Types of Laser Engravers?

There are three main types of laser engravers, each with its own application.

1. Diode lasers:

Diode lasers are small, compact, and low-power lasers that are commonly used for engraving and marking.

They emit a very focused beam of light, this beam is so focused that it can be used to carve intricate designs into wood.

The laser beam is generated by passing an electric current through a semiconductor material.

Given their compact size, ease of use, and ability to produce intricate designs, diode lasers are the best choice for DIY woodworkers, hobbyists, and those looking to start a small engraving business.

Diode engravers can also engrave on acrylic, ceramic, paper, glass, and metal materials

Speaking of carving/engraving wood, here are 7 other power tools that can be used for wood carving.

2. CO2 Lasers:

Used to cut wood, plastic, and other non-metal surfaces, CO2 lasers are medium to high-power lasers found in industries.

The laser used in CO2 laser engravers is typically a gas laser that uses a mixture of carbon dioxide, nitrogen, and helium gases. When the gas mixture is excited by an electrical current, it produces a beam of infrared light that is focused onto the surface of the material.

This beam is then used to etch or engrave various materials, depending on the settings and power of the laser.

Recommended CO2 Laser: xTool P2 & P2S 55W Desktop Laser Cutter

3. Fiber lasers:

If you want to engrave metals, the best choice would be fiber lasers. With a very small focal diameter, fiber lasers are typically used to engrave barcodes and serial numbers on metals.

Fiber lasers use a glass or polymer optical fiber as the gain medium to produce laser light. Known for their high precision, efficiency, and reliability, these laser engravers are typically used on metals and plastics in large industries.

How To Use a Laser Engraving Machine To Engrave Wood

1. Setting Up The Machine

The first step is to unbox your machine and read the instruction manual that comes with it!

For instance, the xTool M1 Ultra Machine comes with a detailed manual and the tools such as screwdrivers to assemble the components into a box configuration.

Next, set the tension of the belts and thread in the middle plate as well as the laser module, limit switch component, and memory card.

Calibrate the laser engraver to ensure that it is accurately positioned and focused. This may involve adjusting the position of the laser module or using the software to perform a calibration routine.

Now, test the laser engraver by performing a simple engraving on a piece of scrap wood. This will allow you to see how the machine performs and make any necessary adjustments to the settings.

2. Designing The Project

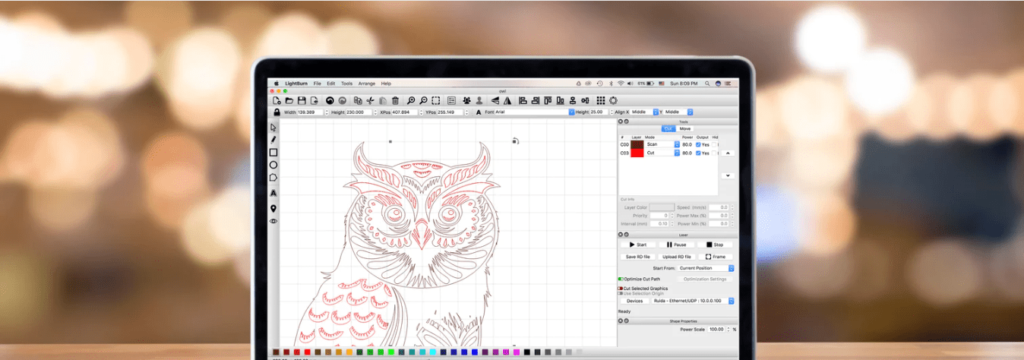

The best way to design your project is to use specialized software designed to control and operate the laser engraving machine.

LaserGRBL is a free, open-source laser engraving software that is commonly used to control and operate laser engravers. It is designed to work with a wide range of engravers and supports a various of file formats. LightBurn is another software that works just as well, but keep in mind that it is paid.

Install the laser engraving software on your computer according to the instructions. This software will be used to control the laser engraver and create your designs.

Connect the laser engraving machine to your computer using a USB cable or a network connection, depending on your specific laser engraver model.

Be sure to select the type of wood you want to do the engraving on.

See section on the recommended wood types for laser engraving

3. Engraving

Once your design is ready, place your piece of wood into the laser engraver and secure it in place. Make sure to wear personal safety equipment before you begin the project.

Load your design into the laser engraving software. This will allow you to control the laser’s movement, adjust the laser settings, and preview the engraving before you start.

Once you are satisfied with your laser settings, start the engraving process. The laser will follow the path of your design and burn the wood to create the engraving.

4. Finishing The Project

Once the engraving is complete, remove the piece of wood from the laser engraver and inspect it for quality. If necessary, make any final adjustments to the laser settings and repeat the engraving process.

When you are done with the engraving, remove the wood from the laser engraver and clean up any debris.

It’s important to follow the manufacturer’s instructions and safety guidelines when using a laser engraver to avoid any potential hazards or damage to the machine.

Recommended Wood Types For Laser Engraving

The results of laser engraving can vary depending on the type of wood, its resin content, its density, and the laser settings used. In general, harder woods produce more defined and deeper engravings, while softer woods are easier to work with but may produce less defined results.

Here are some of the wood types best suited for laser engraving

Balsa wood: This is a lightweight wood that is easy to work with and absorbs laser energy well, making it a popular choice for laser engraving.

Maple wood: Maple is a hard and dense wood that provides a clear, crisp engraving. It is also commonly used for laser engraving due to its uniform grain and pale color.

Basswood: Basswood is a softwood that is easy to engrave and gives a smooth, even surface. It is also relatively inexpensive, making it a good option for large-scale projects.

Cherry wood: Cherry wood is a hardwood that has a fine, even texture, and a rich, reddish-brown color. It is a popular choice for laser engraving due to its attractive appearance and engraving performance.

Alder wood: Alder is a softwood that is easy to engrave and has a fine, even texture. It is also relatively inexpensive, making it a good option for large-scale projects.

Plywood: The versatile material is easy to use and is lightweight apart from having a light, smooth, and consistent texture that responds well to laser engraving.

Safety Tips for Using a Laser Engraver in woodworking

There’s no doubt that laser engravers are powerful tools for woodworking. However, it’s important to follow some basic tips to ensure that you are using the machine safely and responsibly. Here are some things to keep in mind:

Wear Protective Gear

When working with a laser engraver, it’s important to wear protective gear to protect your eyes and skin from the laser beam. This might include safety glasses, gloves, and long sleeves.

Keep Flammable Materials Away

The laser beam generated by a laser engraver can easily ignite flammable materials, such as wood dust, paper, or fabric. To reduce the risk of fire, it’s important to keep flammable materials away from the laser beam at all times.

Avoid Direct Eye Exposure

Never look directly into the laser beam or stare at the laser light while it’s in operation. This can cause permanent damage to your eyes.

Know How To Operate The Machine

Before using a laser engraver, it’s important to familiarize yourself with the machine and understand how to operate it safely and effectively. Read the instruction manual, ask for assistance from the manufacturer or vendor if needed, and only operate the machine when you feel confident and comfortable.

Keep The Laser Beam Focused

The laser beam should always be kept focused on the intended engraving area. If the laser beam strays from the intended area, it can cause damage to other materials or harm someone who comes into contact with it.

Ensure regular maintenance

Regular maintenance is important to ensure that your laser engraver is operating safely and efficiently. This might include checking the laser alignment, cleaning the lens, and checking the electrical connections.

Adhere to safety regulations

Finally, familiarize yourself with this list of safety precautions for using power tools and ensure you adhere to them at all times.

5 Examples of Woodworking Projects You Can Build with a Laser Engraver

With a laser engraver, you can create precise and intricate designs for various applications with ease. Here are five examples of woodworking projects you can build using a laser engraver:

1. Custom signs

You can use a laser engraver to create custom signs for your home, office, or workshop. Whether you want to make a welcome sign, a directional sign, or a sign with your company logo, a laser engraver can help you create a professional-looking sign that will last for years.

2. Wooden Coasters

Coasters are a great way to protect your furniture from scratches and spills. A laser engraver can help you make unique coasters for yourself or as gifts for friends and family.

3. Wooden toys and puzzles:

A laser engraver can help you make challenging and intricate wooden puzzles that are perfect for children and adults alike. You can create jigsaw puzzles, interlocking puzzles, or other types of puzzles to suit your needs.

For example, here’s a laser-engraved wood coin for the fantasy game Dungeons and Dragons (D&D):

And, here is a 3D puzzle box created using laser cutting and engraving tools:

4. Wooden jewelry

You can use a laser engraver to make unique and stylish wooden jewelry, such as necklaces, bracelets, and earrings. Whether you want to make a gift for someone special or sell your creations online, a laser engraver can help you create beautiful and intricate designs.

5. Personalized gifts

Laser engraving on wood is a popular method for creating unique and thoughtful gifts for special occasions and festivals. As laser engraving is 100 percent customizable, you can create a gift that is truly one-of-a-kind. From personalized scented candles and keychains to spoons and wall decor, the possibilities are endless.

Things To Know Before Buying a Laser Engraver for Woodworking

If you are considering buying a laser engraver for your wood projects, here are some important things to keep in mind:

The Type of Laser Engraver

If you are primarily looking to engrave wood only, a diode laser may be the better choice, while a CO2 laser would be better suited for cutting and engraving a wider range of materials.

Engraving Area

Consider the size of the engraving area that you need. Some laser engravers are designed for larger engraving areas, while others are more suited for smaller projects.

Power and Speed

The power of the laser is an important factor to consider. A higher-powered laser will produce deeper and darker engravings, but it will also be more expensive.

Resolution

The resolution of the laser engraver determines the level of detail that can be achieved in the engraving. Higher-resolution lasers produce more detailed engravings, but they are also more expensive.

Control Software

Check what software is compatible with the laser engraver you are interested in. Some laser engravers come with software, while others require you to purchase it separately.

Safety features

Safety features such as interlocks, exhaust systems, and eye protection are important to consider when buying a laser engraver.

Cost

The cost of a laser engraver can vary depending on several factors, such as the brand, size, power, and features of the machine. Generally, desktop laser engravers can range from a few hundred to several thousand dollars, while larger industrial-grade models can cost tens of thousands of dollars.

Ease of use

One of the most important considerations, particularly for those new to laser engraving, is the ease of use. The laser engraving machine you choose should be lightweight, portable, and easy to operate.

Maintenance

Some laser engravers require more maintenance than others, so it is important to find out what is involved in keeping your laser engraver in good working order.

See our article on the best storage systems for power tools

Brand Reputation

Consider the reputation of the brand before purchasing a laser engraver. Look for reviews from other users to get an idea of the quality and reliability of the laser engraver you are interested in.

Our Recommended Laser Machine for Wood Projects

For brevity, we’ve reviewed only 1 product here. See our article on the top budget-friendly laser engravers and cutters for wood crafting.

1. xTool M1 Ultra (4-in-1 Craft Machine)

The xTool M1 Ultra is a revolutionary 4-in-1 crafting machine, combining laser engraving, laser cutting, inkjet printing, and blade cutting in one powerful device. Designed for hobbyists, small business owners, and DIY enthusiasts, the M1 Ultra offers unmatched versatility, allowing users to work with over 1,000 materials for creative and professional projects.

Standout Features of the xTool M1 Ultra:

- 4-in-1 Functionality: Engrave, cut, print, and draw with one machine instead of juggling multiple devices.

- Powerful Laser Performance: Available in 10W and 20W diode laser modules, cutting through wood, acrylic, leather, and more with precision and speed.

- Large Working Area: Spacious 300 x 300 mm workspace, ideal for a wide range of projects, from home décor to custom apparel.

- Ultra-Fast Processing: With speeds of 400mm/s, it offers quick and accurate engraving and cutting, perfect for small businesses looking to scale production.

- Easy 3-Second Tool Swaps: Switch between laser, blade, inkjet, and pen modes effortlessly using 3-Second Easy Swap™ technology.

- AI-Powered Precision: Features Pin-Point™ Positioning for flawless alignment, ensuring perfect designs every time.

- Beginner-Friendly Software: Works with xTool Creative Space, offering one-click settings for 500+ materials and seamless design integration.

- Enhanced Safety Features: Fully enclosed Class 1 laser safety certification, with optional fire safety add-ons for extra protection.

The xTool M1 Ultra is perfect for makers who want precision, speed, and versatility without cluttering their workspace with multiple machines.

Link to Purchase: Get The xTool M1 Ultra Machine Here.

Frequently Asked Questions

Do I need a computer to begin laser engraving?

Yes, you typically need a computer to control a laser engraver. Most laser engravers are operated using specialized software that runs on a computer and communicates with the laser engraver. The software allows you to design your engraving, adjust the laser settings, and control the laser’s movement as it engraves your design.

How much does a laser engraving machine cost?

Entry-level small diode laser engravers can cost between $150 and $500 while hobby laser engraving machines such as the ones made by xTool can cost between $500 and $2000.

The cost of entry-level CO2 laser engraving machines can range from $400 to over $5000. Fiber laser engravers have price points between $4000 and $11000.

Can a 10-watt laser cut wood?

Generally, a 10-watt laser would be suitable for cutting through thin sheets of wood. If you are looking to cut through thicker or denser pieces of wood, you may need a more powerful laser or a different cutting method.

What is the difference between a laser engraver and a laser cutter?

A laser engraver is mainly used to create detailed two-dimensional images on a surface by etching into the material.

A laser cutter uses a higher output power to cut through the material and produces cuts of various shapes and sizes.

Is a laser engraver a good investment for woodworkers?

Sure is! Laser engraving can open a new world of possibilities for woodworkers. By combining speed, precision, and accuracy in one machine, laser engravers are able to produce intricate designs and patterns quickly and efficiently.

Final Verdict

Whether you’re creating small batches of personalized gifts or large production runs, investing in a laser engraver can help you take your woodworking projects to the next level.

Not only are they efficient and precise, but they also offer an extra level of customization that can make your projects stand out from the rest.

Enjoy our articles? You can follow us on Pinterest for more woodworking power tools tips and tricks.

Save on selected power tools from top brands - Shop Now on Zoro.