YOUR NO 1 WOODWORKING POWER TOOLS RESOURCE WEBSITE

Planer vs Jointer: Which is More Important For Woodworking?

Disclosure: If you click on some of the links, we may earn a small referral fee. Please know that we only recommend products that we use and believe will add value to our readers.

When setting up your workshop or thinking about the next piece of equipment to add to your collection, the decision of whether you should buy a planer or a jointer usually comes up sooner or later. Both tools, while having distinct functions, are critical in refining your raw lumber into a masterpiece. But which one is more important? And when do you use one over the other?

In this comprehensive guide, we aim to help you understand the differences between a planer and a jointer, their role in your woodworking projects, and ultimately guide you in making an informed decision that best suits your needs.

Whether you’re starting a new woodworking project, looking to invest in new tools, or simply curious about the whole “Planer vs Jointer” discussion, this article has got you covered. Let’s dive right in.

In the meantime, you can take a look at our list of essential power tools for woodworking.

Planer vs Jointer – Summary Table

|

|

PLANER | JOINTER | |

|

Application |

Achieving uniform thickness | Flattening and squaring edges | |

|

Lumber Surfaces |

Uniform thickness, parallel surfaces | Perfectly squared single edges | |

|

Blades |

Positioned above the table | Embedded in the table | |

|

Surface Flattening |

Consistent flatness and smoothness | Perfectly flat surface | |

|

Thickness Control |

Control over thickness adjustment | No control over thickness | |

|

Dust Collection |

Often equipped with built-in systems | Varies by model | |

|

Automation |

Adjustable depth and feed rate settings | Requires manual operation | |

|

Price |

Generally less expensive | Larger floor models are expensive |

Planer – An Overview

A planer is a power tool used to smooth and level the surface of rough lumber, making it suitable for various woodworking projects. It is designed to remove a thin layer of material from the wood, resulting in a smooth and consistent thickness.

The primary function of a planer is to ensure that your lumber is flat, parallel, and consistent in thickness. It eliminates imperfections such as rough saw marks, unevenness, and warping that may be present in rough-cut or reclaimed wood. With a planer, you can transform rough lumber into beautifully finished boards ready for further woodworking.

Parts of a Planer

Let’s take a look at the main components of a planer

Infeed and Outfeed Tables: The infeed table is where you feed the rough lumber, while the outfeed table supports the wood as it exits the planer. These tables provide stability and ensure a smooth and even feed throughout the planing process.

Depth Adjustment: A planer allows you to control the depth of cut, enabling you to remove the desired amount of material from the wood surface. This adjustment can typically be made using a depth adjustment wheel or handle.

Types of Wood Planers

Planers come in various types:

Surface Planer: This type of planer is designed to flatten and smooth the surface of the wood, resulting in an even thickness across the entire board.

Thickness Planer: As the name suggests, a thickness planer focuses on achieving a consistent thickness throughout the board. It is especially useful when you need to create boards of the same thickness for specific woodworking projects.

Benchtop Planer: A compact and portable option, benchtop planers are ideal for smaller workshops or woodworking enthusiasts who need a versatile yet space-saving machine.

Stationary Planer: They are larger, more powerful machines often used in professional workshops or woodworking businesses. They offer high capacity and precision, making them suitable for heavy-duty projects.

Relevance of Planers in Different Woodworking Projects

The versatility and benefits of planers make them an essential tool for woodworkers of all skill levels. Here are some key areas where planers prove their worth

Thickness Control

A planer enables you to achieve precise thickness control, ensuring uniformity in your boards. Whether you need to reduce the thickness of a piece of wood or make multiple boards the same thickness for a project, a planer comes in handy.

Surface Smoothing

Planers excel in flattening and smoothing rough lumber. They can quickly remove imperfections such as cupping, twisting, and warping, resulting in a flat and even surface ready for further woodworking processes.

Stock Preparation

Planers are invaluable when it comes to preparing rough lumber for various woodworking projects. They remove the rough outer layer, revealing the beautiful grain and making the wood easier to work with.

Dimensional Consistency

Planers ensure that all your boards have consistent thickness, even if they are store-bought. By running your lumber through a planer, you can achieve uniformity, which is crucial for projects like tabletops, cabinets, or any piece that requires precise joinery.

Our Recommended Planer Option

One highly recommended planer option is the DEWALT Thickness Planer, specifically the DW735X model. This planer offers a powerful and efficient performance, with features that make it a popular choice among woodworkers. It has a three-knife cutterhead that delivers clean and smooth cuts, while its two-speed gearbox allows you to adjust the feed rate for optimal results. Additionally, the DW735X comes with an extra set of disposable knives, a dust hose adapter, and a material removal gauge for added convenience.

Whether you’re a beginner or an experienced woodworker, having a reliable and high-quality planer like the DEWALT DW735X can significantly enhance your woodworking projects.

Jointer – An Overview

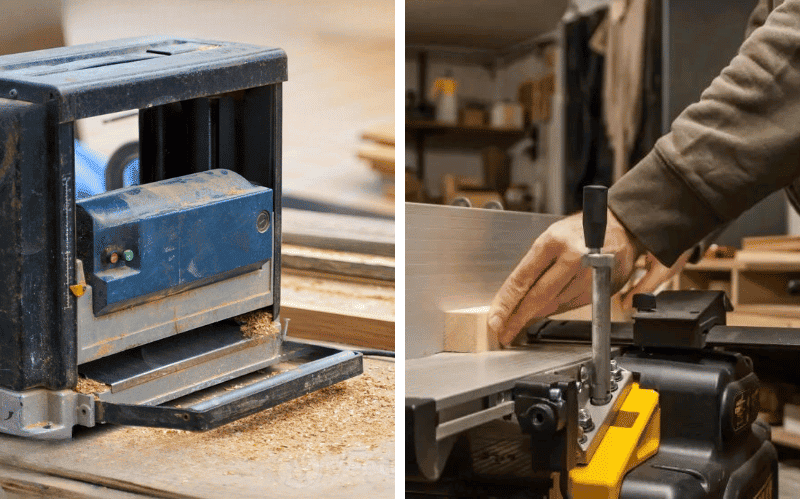

A jointer is a woodworking machine designed to create flat and straight edges on boards. It is specifically used to remove any twists, warping, or unevenness in lumber, resulting in perfectly squared and smooth edges. Jointers are primarily used to prepare wood for joining and further shaping.

For more details, see our complete guide to the Jointer power tool.

Parts of a Jointer

Here are the main components of a jointer:

Infeed Table: This is where you feed the wood into the jointer for processing. It provides support and stability to the board as it moves through the machine.

Cutterhead: The cutterhead is a rotating disc equipped with sharp blades that eliminate material from the board’s edge, creating a smooth surface.

Fence: The fence acts as a guide, ensuring that the edge being processed remains straight and perpendicular to the board’s face.

Guard: The guard serves as a safety feature, protecting you from accidental contact with the rotating cutterhead.

Types of Wood Jointers

Jointers come in various types to accommodate different woodworking needs.

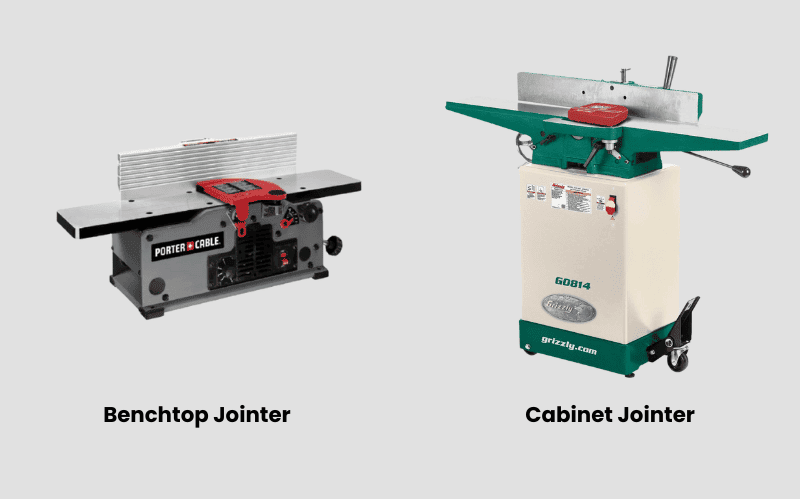

Benchtop Jointer

These compact and portable jointers are suitable for smaller workshops or woodworking enthusiasts with limited space. They offer sufficient power and functionality for most DIY and hobbyist projects.

Floor-standing/Cabinet Jointer

These larger and more powerful jointers are typically found in professional workshops and woodworking businesses. They provide increased capacity, precision, and stability, making them suitable for heavy-duty projects.

Spiral Cutterhead Jointer

Some jointers are equipped with spiral cutterheads, which consist of multiple individual carbide inserts. This design provides smoother and quieter operation while reducing tear-out.

Relevance of Jointers in Different Woodworking Projects

Here are some key areas where jointers prove their importance

Edge Joinery

Jointers are essential when it comes to creating perfectly flat and straight edges on boards for edge-to-edge joinery. This is particularly important when working on projects like tabletops, cabinets, and furniture where seamless joints are crucial.

Surface Preparation

Jointers excel in preparing rough lumber by correcting common wood defects such as warping, cupping, bowed, or twisted boards. By running rough lumber through a jointer, you can achieve a flat and smooth surface, ready for further woodworking processes.

Stock Dimensioning

Jointers are integral for achieving consistent thickness and width across a workpiece. They help in preparing lumber to the desired dimensions, making it easier to work with and ensuring uniformity in the final project.

Our Recommended Jointer Option

One highly recommended jointer option is the Porter-Cable PC160JTR Bench Jointer. This benchtop jointer offers a solid combination of power, functionality, and affordability, making it ideal for DIYers and woodworking enthusiasts. It features a 6-amp motor, a two-knife cutterhead, and a 6-inch cutting width, providing ample capacity for most small to medium-sized woodworking projects. The compact size of the bench jointer makes it suitable for workshops with limited space, and its user-friendly design ensures ease of use for beginners.

With the Porter-Cable PC160JTR Bench Jointer, you can confidently tackle a wide range of woodworking tasks, including edge joining boards and surface preparation.

Planer vs Jointer (Side-by-Side Comparison)

Now that we have a good understanding of what a planer and jointer are, let’s compare them side by side across various aspects.

Applications

The planer is mainly used for achieving uniform thickness throughout the boards and creating parallel surfaces. On the other hand, jointers are primarily used for flattening and squaring the edges of boards, creating flat and straight surfaces.

Blades

In terms of the blades, planers have the blade positioned above the table and cut from the top, while jointers have the cutting knives embedded in the table, and the wood passes over them.

Surface Flattening & Smoothness

Planers ensure consistent flatness and smoothness across the entire surface of the board. Jointers, on the other hand, achieve a perfectly flat surface, but the limited width they can handle may result in inconsistent smoothness.

Edge Straightening and Squareness

This is where jointers shine. They provide precisely square and straight edges, making them ideal for edge joining boards smoothly. Planers, however, cannot effectively square the edges of a board on their own.

Thickness Control and Accuracy

Planers offer greater control over thickness adjustment, allowing for precise dimensioning. Jointers, on the other hand, do not provide control over thickness and are mainly focused on surface flattening.

Dust Collection & Safety

Planers are often equipped with built-in dust collection systems and safety features like blade guards. Jointers commonly include safety features such as blade guards, but their dust collection may not be as efficient.

See our complete guide to dust collection in woodworking shops

Automation

Planers generally offer more automation with features like adjustable depth settings and feed rate control. Jointers have more manual operation, requiring the woodworker to guide the wood over the cutterhead.

Price

Planers are generally less expensive than jointers, although prices can vary depending on the type and size of the equipment. Jointers, especially larger floor-standing models with higher horsepower, tend to be pricier.

Choosing between a Planer or Jointer For Woodworking Projects

Here are some factors to keep in mind

Understanding the Specific Needs of Your Projects

Assess the type of woodworking projects you’ll be working on. If you primarily work with rough lumber that requires flattening, leveling, and smoothing, a jointer will be beneficial. On the other hand, if you need consistent thickness throughout your boards or are looking to dimension stock to a specific size, a planer will be more suitable.

Budget Considerations and Space Requirements

Both planers and jointers come in various sizes and price ranges. Consider your available budget and workshop space. Planers, especially benchtop models, are generally more affordable and compact, making them a good choice for smaller workshops or hobbyist woodworkers. Jointers, particularly floor-standing models, tend to be larger and pricier but offer more capacity and precision.

Recommendations for Different Skill Levels and Project Types

For beginners or those getting started in woodworking, a portable benchtop planer may be a practical choice. It provides versatility and ease of use without breaking the bank. For more experienced woodworkers tackling larger projects or working with wider boards, investing in a stationary planer or a floor-standing jointer may be worth considering.

How Planers and Jointers Complement Each Other in a Woodworking Workflow

It’s important to note that planers and jointers are not mutually exclusive. In fact, they often complement each other. While jointers excel at creating flat and straight edges, planers help achieve consistent thickness and smooth surfaces. By incorporating both tools, you can efficiently mill and prepare your lumber for various woodworking projects, ensuring accuracy and high-quality results.

Frequently Asked Questions (FAQs)

Can I use a planer instead of a jointer, or vice versa?

While it is possible to use a planer to flatten one face of a board with the help of a jig or sled, it does not offer the same level of precision as a jointer when it comes to edge straightening and surface flattening.

Do I need both a planer and a jointer for woodworking?

It depends on the woodworking projects you undertake and the level of precision and efficiency you desire. If you frequently work with rough lumber or need precise edge joints, having both a planer and a jointer can greatly enhance your woodworking capabilities. However, if budget or space constraints are a concern, you can achieve similar results by using alternative methods or tools in combination with a planer or a jointer.

Should I buy a jointer or planer first?

It is generally recommended to invest in a thickness planer first. The tasks of a jointer can be achieved through alternative methods.

Which tool is more suitable for smoothing rough lumber?

When it comes to smoothing rough lumber, a jointer is more suitable.

Are there such things as a planer/jointer combo?

Yes, there are planer/jointer combination machines available in the market. These machines offer the functionality of both a planer and a jointer in a single unit. They can switch between planing and jointing modes, allowing you to perform both tasks without the need for separate machines. However, it’s important to note that planer/jointer combos often come at a higher cost and may have limitations compared to standalone machines. One recommended model is the Jet Planer/Jointer Combo (707410).

What is a thicknesser and how does it compare with the planer or jointer?

The terms “thicknesser” and “thickness planer” are often used interchangeably. They both refer to the same woodworking machine that focuses on achieving a uniform thickness in the boards.

Can I use a table saw as a jointer?

While a table saw can perform certain jointer-like functions, it does not fully replace the capabilities of a dedicated jointer. A table saw can help you achieve straight edges by using a straight-edge guide or a tapering jig. However, it is important to note that a table saw does not flatten or square the edge as effectively and consistently as a jointer. If precise edge jointing is a requirement in your woodworking projects, a dedicated jointer is recommended for achieving optimal results.

Final Verdict

Remember, woodworking is a journey of learning and honing your skills. As you gain experience and take on more complex projects, you may find that acquiring both a planer and jointer becomes necessary. Regardless of which tool you choose or when you decide to invest in them, always prioritize safety, proper usage, and maintaining the tools for optimal performance.

Enjoy our articles? You can follow us on Pinterest for more woodworking power tools tips and tricks.

Save on selected power tools from top brands - Shop Now on Zoro.