YOUR NO 1 WOODWORKING POWER TOOLS RESOURCE WEBSITE

Cyclone Woodworking Dust Collection Systems (Ultimate Guide + FAQs)

Disclosure: If you click on some of the links, we may earn a small referral fee. Please know that we only recommend products that we use and believe will add value to our readers.

Cyclone Dust Collection Systems

The cyclone dust collection system is a great addition for woodworkers with modest workshops who want to capture even the smallest dust particles.

Dust collection is a topic that has generated many controversies among woodworkers. Perhaps, it is because setting it up may cost you more than a regular table saw, but it isn’t fun to operate, neither does it show in the projects you build.

You may not want to hear this, but investing in a good quality dust collection system will be the most important workshop decision you will ever make.

Not only does dust from workshop activities pose safety threats, but they also hinder good results.

Keep reading this article and you will find out everything you need to know about cyclone woodworking dust collection systems and how they can save your life.

Related:Dust Management in Woodworking: 9 Best Practices for a Cleaner Workshop

The Three Types of Workshop Dust

Before jumping into dust collection systems, it is important to first understand the different kinds of dust we are up against.

Chips:

These are created by planers and jointers. They are big, can be seen, but they cannot be inhaled. They make your shops look dirty, but they pose little health risk unless there are enough of them on the floor to make you slip.

Dust Particles:

The next type is the dust that settles everywhere in your workshop. They are usually produced from saws and sanders. These dust particles are relatively large (10 microns or less). We may inhale them but our bodies can easily manage them through sneezing and coughing.

Fine Dust:

This is the most harmful type of dust. They are so small (under 2.5 microns) that the naked human eye cannot see them, except through slight cloudiness where a beam of light shines through the air. This kind of dust doesn’t make our shops look messy but when inhaled, they stick to the surface of the lungs. If not checked early, this could lead to permanent damage or even cause death.

Related Article: How To Be Safe When Using Power Tools For Woodworking

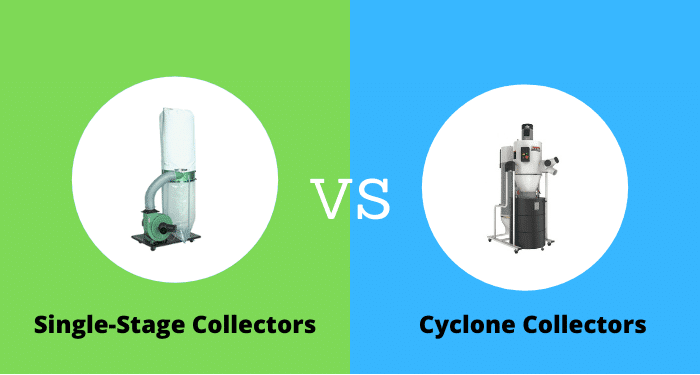

Single-Stage vs Cyclone Dust collectors

Single-Stage Dust Collectors

Single-stage dust collectors have been around for decades. Here is a quick overview of them.

How single-stage dust collectors work:

They feature a motor connected to an impeller (a rotating pump with a series of blades). Wood chips and dust-filled air are drawn in via the impeller. The wood chips and heavy dust particles fall into a waste container (usually a canister or plastic bag). Air is then vented out through a filter bag/canister and back into your store. This air will usually still contain very fine dust particles.

Characteristics of the single-stage dust collectors:

- The airflow capacity of a typical single-stage dust collector is around 500 CFM ( Cubic feet of air per minute)

- They can be used in shops where the ducting is short and has minimal bends.

- Their filter bag/canisters are rated between 10-30 microns (i.e the size of fine dust they can screen out)

Why single-stage dust collectors are not recommended:

- Their filters clog quickly which leads to a drop in its CFM. You will need to constantly keep the filters clean to solve this issue.

- Their 10 micron canister filter rating cannot protect you from the finest dust particles (which is around 1 micron).

- Since dust and chips both go through the impeller, nails or screws could be captured. This can lead to sparks and even cause fire.

Cyclone Dust Collectors

Sometimes called a two-stage dust collector, the cyclone collectors were created to deal with the limitations of the single-stage collectors.

How do cyclone dust collectors work?

Unlike single-stage collectors, cyclone collectors treat wood chips and dust in two stages. The impeller, which is connected to the motor that sits on top of the collector creates a cyclonic force that causes air (fine dust and wood chips) to spin around in the cone. Heavy wood chips fall into the waste drum, while fine dust particles are drawn up through the impeller into the filter canisters (this is the first stage). At the filter canisters, the cleaned air is separated from fine dust and is vented out while the fine dust particles fall into the fine dust bag (this is the second stage).

Characteristics of the cyclone dust collectors:

- Most cyclone dust collectors come with high-efficiency filters that can remove the smallest of dust particles, down to 1 micron.

- They usually have a higher CFM rating than single-stage collectors.

- The two-stage process of separating heavier materials from fine particles means that the filters will clog up much slower than the single-stage collectors.

- Less clogging means less need for cleaning.

- Also, the canister filters cannot get damaged easily since large wood chips don’t come in contact with it.

- Cyclonic filter canisters are usually equipped with a flapper handle to make it easy for you to clean the filter using compressed air.

- Cyclone collectors do the best job of removing as much fine dust as possible, hence they are the most recommended dust collection system for any woodworking shop.

Factors To Consider Before Buying a Cyclone Dust Collector

Now that we have all agreed that cyclone dust collectors are the best dust collection systems to use for woodworking, let us now look at some factors to consider before choosing one for your workshop.

Airflow

Measured in cubic feet per minute (CFM), this is how much air an impeller can move at its maximum speed using both air rate and air volume. A good collector should have a high CFM rating. This way, it can generate a high volume of air with enough speed to move the chips – dust mixture from the machine through the ducting pipes and into the collector.

Filtration Efficiency

The cyclone dust collector should be able to trap the tiniest of dust particles as this is the reason why you are using a dust collector in the first place. You should go for collectors with HEPA filters if possible as they provide the best level of protection against fine dust.

Portability

Most cyclone collectors are either portable (with rolling wheels) or wall-mounted. For a woodworking shop, portable collectors are the most recommended as they offer you more flexibility when working with different machines.

Here are 9 portable dust collectors that we recommend

Hose Length and Diameter

This will depend on the portability of the collector you choose, your shop’s design, and the diameter of the dust ports on your existing machines. Bear in mind that cyclone collectors generally come with adapters and hoses, but they may not work well for you. Be ready to purchase some extra items to enable you to set up the system well.

Power Requirements

Some cyclone collectors run on 110 volts supply, others may require a dedicated 230 volts supply. Before purchasing a collector, make sure you have the required circuit needed to run it or you can add one to your distribution panel.

Noise Level

Remember the dust collector will be used concurrently with another workshop machine. This makes high noise levels inevitable. To combat this, it is necessary to use some form of hearing protection when working.

Waste Drum Capacity

If your workshop produces a lot of wood chips, you will save time with a large waste drum. To make moving the drum around easier, most manufacturers equip their collectors with wheels.

Related Article: Where is the Best Place to Buy Power Tools | 14 Top Power Tool Stores

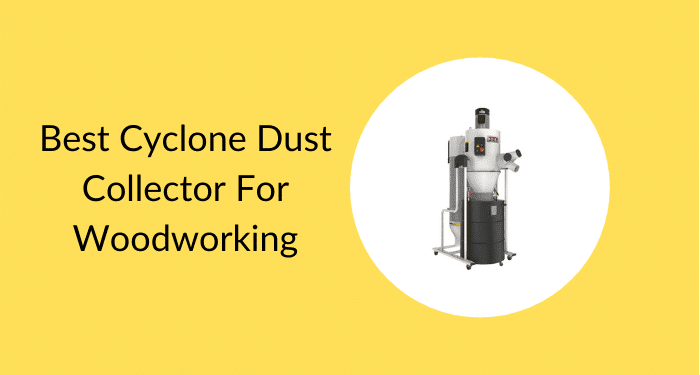

What is The Best Cyclone Dust Collector For Woodworking

The best dust collection system for your workshop is a setup that is capable of handling large volumes of wood chips and keeping as much fine dust as possible away from your shop’s air and lungs.

From my experience, the JET, 3HP, Cyclone Dust Collector ticks all the boxes.

With an airflow of 1240CFM chips-dust mixture can be easily moved from your machine through the ducting pipes into the collector.

Its 66 gallon drug capacity means that you never have to worry about constantly emptying wood chips.

Its overall filter efficiency of 1 micron means that even the smallest dust particles get to stay away from your lungs.

Although this is a heavy-duty machine, its motor is relatively silent.

This collector comes with inbuilt wheels that let you move it around your workspace easily.

Lastly, let’s not forget JET’s impressive 5 years warranty meaning you can rely on this collector for a long time to get the job done.

Get the JET 1,963 CFM Max Flow, 3HP Cyclone Dust Collector available at:

Need more options? See our review of the 7 best cyclone dust collectors for small shops

Frequently Asked Questions

Q. Is a cyclone dust collection system worth the investment?

It is easy to get caught up in the initial purchase price, but take a step back and consider the return on your investment. Like many, if not all workshop machines, a cyclone collector should last you a lifetime. The only components that may need replacing are the plastic bags, motor and maybe the power switch. These are no big deal.

Q. What are the advantages of using a cyclone dust collection system?

Cyclone dust collectors contain two compartments where dust is separated and filtered. Large wood chips are deposited into the lower drum, while small dust particles move through the filter and then into the fine dust bag. This makes them more efficient at removing and containing as much dust as possible.

Q. How much CFM do I need for a cyclone dust collector?

According to a study made by billpentz, stationary workshop tools need about 1000CFM of airflow to have good dust collection and only about 350CFM for good chip collection.

Q. I have a shop vacuum. Do I still need a cyclone dust collector?

Shop vacuums can handle dust but you will still need to protect yourself from fine particles when cutting wood. Shop vacuums may work for small shops that don’t use power tools, but for shops equipped with the essential woodworking power tools, a cyclone dust collection system is a must-have.

See this article for a full comparison between the shop vac and a dust collector

Conclusion

Fine dust accumulation in the lungs of a human can lead to serious respiratory diseases. By investing in a trusted cyclone dust collection system, you can minimize if not eliminate fine dust from your woodworking shop.

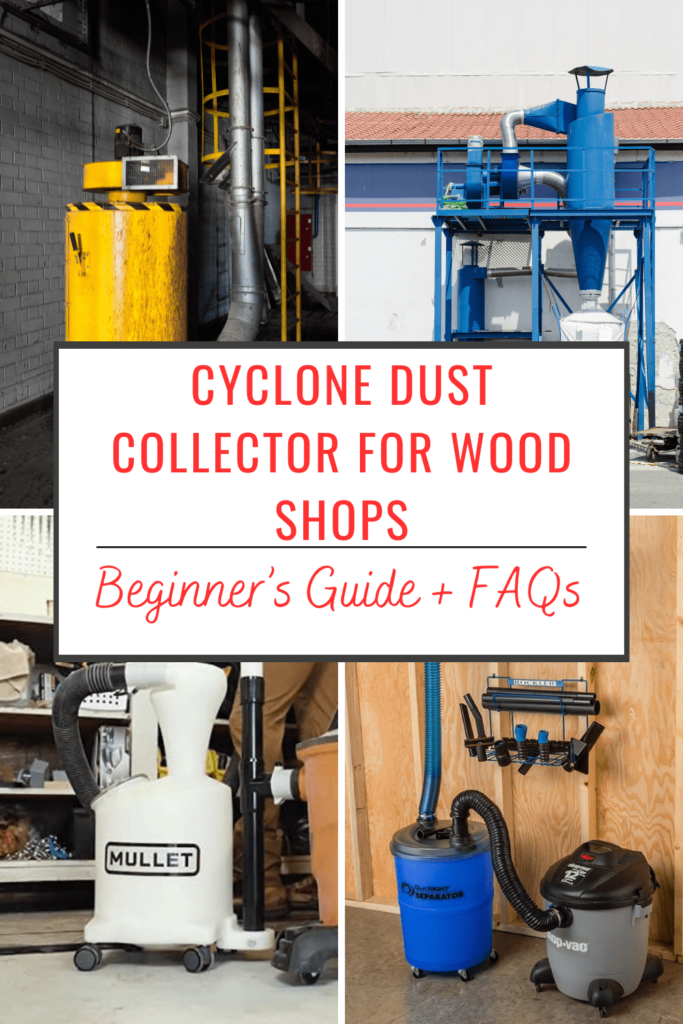

Pinterest Image

Enjoy our articles? You can follow us on Pinterest for more woodworking power tools tips and tricks.

Save on selected power tools from top brands - Shop Now on Zoro.