YOUR NO 1 WOODWORKING POWER TOOLS RESOURCE WEBSITE

Band Saw Maintenance and Blade Tensioning: A Beginner’s Guide

Disclosure: If you click on some of the links, we may earn a small referral fee. Please know that we only recommend products that we use and believe will add value to our readers.

As a woodworker who often operates a band saw, you’re aware that having this tool in top working condition is essential for optimum performance. A dull, slow-moving, or untidy band saw not only affects the quality of your cuts but could also pose a significant safety hazard. Among the critical areas of band saw maintenance, blade tension adjustment holds a significant place since a poorly tensioned blade can lead to inaccurate cuts or even damage your saw.

This article aims to guide you through the necessary steps of band saw maintenance, with a particular emphasis on blade tensioning. We’ll delve into the regular upkeep of your band saw, understanding blade tensioning nuances, best practices for blade tension adjustment, and how to troubleshoot common blade tension issues. By the end of this guide, you should have the know-how to maintain your band saw for optimal performance and long life.

Need a high-quality band saw for your projects? We’ve reviewed 6 of the best band saws under $500

Regular Band Saw Maintenance

To ensure your band saw stays in top working condition, it’s important to implement a regular maintenance routine. By dividing the maintenance tasks into daily, weekly, and monthly activities, you can keep your band saw operating smoothly and extend its lifespan.

Suggested Article: An Overview of The Band Saw for Woodworking (Types & Applications)

Please note that the maintenance instructions outlined in this article are primarily tailored for stationary benchtop band saws rather than handheld or portable band saw models.

Daily Maintenance

- Cleaning and debris removal: Start each day by thoroughly cleaning your band saw, removing any sawdust, chips, or debris that may have accumulated. Pay attention to the grooves, band wheels, blade guides, vise jaws, and machine surfaces, using a stiff brush or a vacuum to ensure a clean working area.

- Lubrication and rust prevention: Check the levels of sawing fluid and lubricants and top them up as needed. Lubricate any necessary parts, such as the bearings, according to the manufacturer’s recommendations. This helps reduce friction, maintain smooth operation, and prevent rust or corrosion.

Related articles:

Dust Extraction in Woodworking: 9 Best Practices for a Cleaner Workshop

How To Clean Saw Blades in 15 Minutes (A Step-By-Step Guide)

Weekly Maintenance:

- Adjustment of guide blocks and bearings: Inspect the guide blocks and bearings and ensure they are properly aligned and adjusted. Replace any worn or damaged parts promptly to avoid premature blade wear and ensure accurate cuts.

- Calibration and alignment checks: Check the alignment of the band wheels regularly to ensure they are parallel and in proper alignment. Aligning the wheels correctly prevents premature blade wear and ensures optimal performance.

Monthly Maintenance

- Evaluate blade tension: A blade that is set to the correct tension will result in accurate cuts and prolong the life of the blade. Consult the manufacturer’s recommendations for the appropriate tension level.

- Clean the hydraulic system: Clean the system to maintain the free flow of fluids through all nozzles and prevent any issues that may compromise the performance of the band saw.

- Inspect vises, belts, and drives: Evaluate the condition of the vises, belts, and drives. Replace any worn-out or damaged parts to maintain optimal performance and avoid unexpected breakdowns.

Understanding Blade Tensioning

Blade tension refers to the amount of pressure applied to the blade to keep it taut and in optimum cutting condition. It directly affects the cutting performance of your band saw. Insufficient tension can cause the blade to wander, resulting in inaccurate cuts and difficulty following a desired pattern. On the other hand, excessive tension can lead to increased blade wear, motor strain, and even blade breakage.

Recommended tension levels may vary depending on the type of cut you are performing. For general cutting tasks, a medium tension level is usually sufficient. For resawing or making deep cuts, higher tension levels are required to maintain blade stability and cutting precision.

Recognizing the signs of improper blade tension is essential to ensure your band saw is operating optimally. Some common indicators of incorrect tension include uneven or wavy cuts, excessive heat on the blade or motor, frequent blade drift, and premature blade wear.

Blade Tensioning Best Practices

Step-by-step guide on tensioning a band saw blade

- Begin by fitting your band saw with a well-aligned and straight blade.

- Drop the upper guide assembly to a few inches above the saw table and remove the blade guard assembly if necessary.

- Retract the blade guide assembly and thrust bearing all the way back, and loosen and remove each of the guide blocks on both the upper and lower guides.

- Carefully slide the blade onto each wheel, roughly centering it on each tire.

- Increase the blade tension until it becomes taut. You can visually assess the tension by sighting the blade from above. Increase the tension until the blade stops straightening out, and then give it an additional 1/2 to a full crank more.

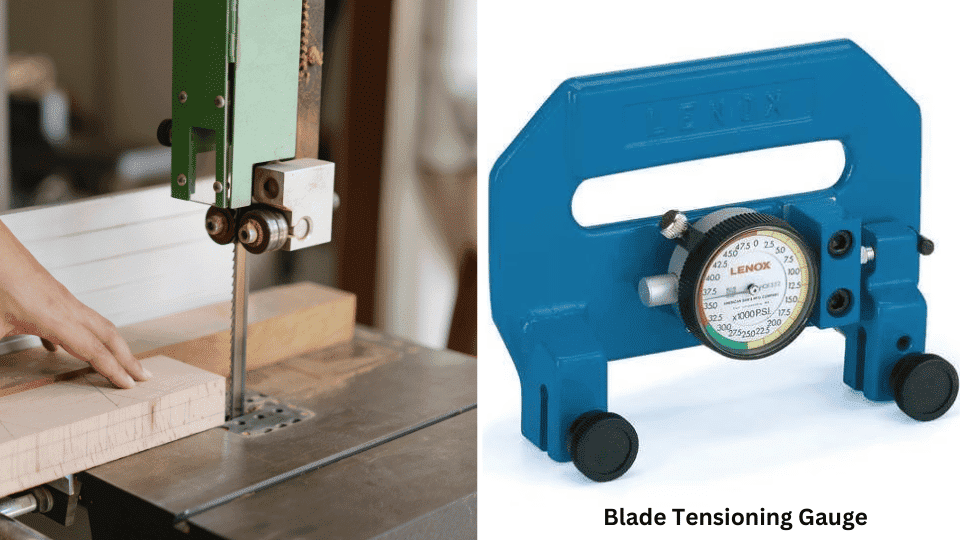

Tools and equipment for accurate tensioning

- Tension gauge: Although a tension gauge may come with a higher price tag, we highly recommend investing in this tool for precise and consistent blade tensioning.

- Wrench or tension release lever: These tools are used to adjust the tension of the blade by tightening or loosening the tensioning system of your band saw.

Factors to consider when determining the ideal tension

- Blade thickness: Thicker blades usually require higher tension compared to thinner blades.

- Material and cut type: Consider the material you are cutting and the type of cut (straight or curved) you want to make. Different cuts may require different tension levels for optimal results.

Troubleshooting Band Saw Blade Tensioning Issues

Even with proper maintenance and regular tension checks, blade tension issues may still arise. Here are some common problems and how to address them.

Identifying and resolving blade drift

Blade drift refers to the blade deviating from a straight cutting line. If you notice your cuts veering off course, it may be due to blade drift caused by incorrect tension. To resolve this issue, start by checking your blade alignment and tension. Adjust the tension accordingly, making sure it is evenly distributed across the blade. If the issue persists, you may need to realign your blade guides or consult the manufacturer for further troubleshooting steps.

Correcting uneven blade wear

Uneven blade wear may occur if the blade is not properly tensioned or if the guides are not adjusted correctly. If you notice one side of the blade wearing more rapidly than the other, check your tension and adjust it as needed, ensuring equal tension on both sides of the blade. Also, evaluate and readjust your blade guides to ensure they are properly supporting the blade during cuts.

Dealing with blade fatigue and breakage

Over time, blades can become fatigued and eventually break if they are constantly under- or over-tensioned. If you experience frequent blade breakage, inspect the tension of your blade. Avoid overtensioning or undertensioning, as this can put excessive stress on the blade and lead to premature fatigue.

Frequently Asked Questions (FAQs)

How often should I check and adjust blade tension?

Blade tension should be checked regularly, especially when you change blades. Adjustments should be made if you notice any signs of improper tension or if you’re working on different materials or cuts that require specific tension levels.

Can I use the same tension for different blade types?

It’s best to consult the manufacturer’s recommendations for each specific blade type you plan to use. The thickness and width of the blade, as well as the cutting application, can all impact the ideal tension needed for effective and safe cutting.

Are there any safety precautions to follow during blade tensioning?

Safety should always be a priority when working with band saws. When tensioning the blade, ensure that the machine is turned off and unplugged. Use proper tools, such as a tension gauge, to accurately measure and adjust the tension. Avoid placing your hands or fingers near the blade during tensioning, and always follow the manufacturer’s guidelines and safety instructions.

What are the signs that indicate a blade needs replacement?

These include excessive wear on the teeth, broken or missing teeth, visible cracks or deformities in the blade, or a blade that no longer cuts smoothly or accurately. If you notice any of these signs or experience consistent issues with your cuts, it’s best to replace the blade to ensure optimal performance and safety.

Concluding Remark

Implementing the tips and knowledge shared in this article will keep your band saw in optimal condition, ensuring precise and accurate cuts while prolonging the lifespan of your blades.

If you’re undecided about whether to choose a band saw or a scroll saw for your next woodworking project, we’ve got you covered in our comparison.

Enjoy our articles? You can follow us on Pinterest for more woodworking power tools tips and tricks.

Save on selected power tools from top brands - Shop Now on Zoro.

![Top 10 Best Circular Saw for Beginners [Expert Picks + Buying Guide] Best Circular Saw for Beginners - Featured Image](https://diywoodenplans.com/wp-content/uploads/2023/04/Best-Circular-Saw-for-Beginners-Featured-Image.png)